Ultimate Strength. Ultimate Longevity.

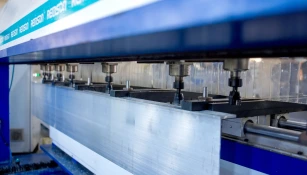

As the world continues to grow every single day, demand for infrastructure grows as well. In recent years, the construction industry has transformed their process completely. The technology is taking place of traditional construction methods. Aluminium Formwork Systems are much more sturdy, they have longer lifespan and they save a lot of money in the long run.

The traditional scaffolding methods using plywood and timber are inadequate to bear the high load of concrete in bigger construction projects. They free up a lot more space, they need less maintenance and require less labour to manage. Also, they can be reused many more times compared to traditional formwork and scaffolding systems.

Remson Aluminium Formwork Systems makes construction process for Walls, Floor Slabs, Columns, Beams, Stairs, Window Hoods, AC Hoods, and Balconies faster and much more cost effective.